Bravu's Series of Experience's - Chapter #1

MANUAL LABOUR vs AUTOMATION

Are you giving your products a fair chance in your market space? Finding the right support to advise on your packaging and production process can be the difference between your business Sinking, Surviving or Thriving.

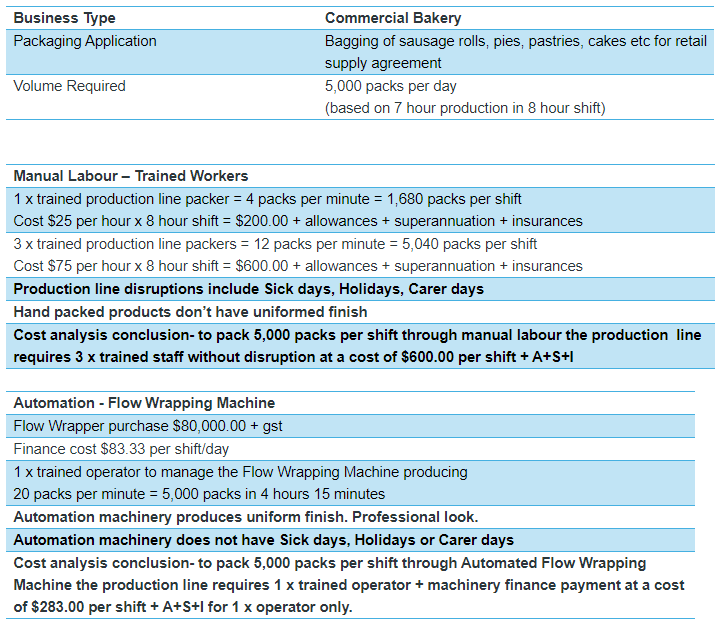

Last month we were approached by a fast-growing commercial bakery that had just secured a B2B contract requiring them to double their production volumes of their pastries and donuts to 5,000 packs per day.

Operating out of Western Sydney and supplying the local market for the past 5 years, the new contract would see them extend their supply to Melbourne and Brisbane.

To meet the increased production volume this growing business had to decide between the addition of Manual Labour or introducing Automation machinery.

Considering all factors including contractual obligations and their current production line capabilities Bravu presented the following assessment for their appraisal.

Option #1

Assign 3 trained production line packers to meet the contractual volume requirements of 5,000 packs per day at a cost of $600.00 per 8 hour shift (7hr production time) including tax + allowances + superannuation + insurances.

Sick days, Holidays & carer days also to be considered. Finished product is hand packed without uniformed finish.

Option #2

Invest $80,000 on a horizontal Flow Wrapping Machine. Finance cost of $83.33 per day. Assign 1 x trained operator to manage 20 packs per minute. 5,000 packs will be completed in 4 hours 15 minutes with a cost of $283.33 per shift including tax + allowances + superannuation + insurances for the operator. Automation machinery produces a uniformed finish with a professional look.

After considering the options presented the customer went with option 2. They currently meet their contractual requirements saving $316.67 and 2 hours 45 minutes production time per shift.